- Product Info

- Further Info

- Video

- Delivery

- Related Products

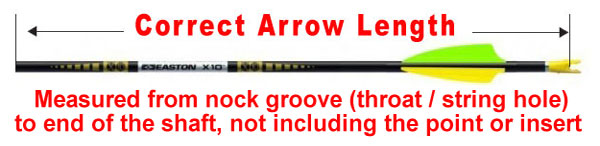

Spine and max length shown in brackets measured from nock groove

Ultralight Pro arrows are designed and built to the demanding specifications of top field, FITA and 3D archers. If you demand the best from your equipment, count on Ultralight Pro arrows to deliver exceptional performance shot after shot. At +/-.001" Straightness and guaranteed to weigh within 1 grain per dozen, you will not find a more accurate or more consistent arrow.Custom Made Arrows Include -

• One Piece Stainless Steel Points (100 or 80g)• Elite Plasti-Fletch Vanes• G-Nock + Uni-busing (set for finger release)*If you need help in your spine selection click here - (Charts)Important:

*We have tried to make it as simple as possible to order your custom made arrows, but should you have any special requirements (such as set nock for compound release), please e-mail first with any questions.

SAFETY INFORMATIONOVERDRAW WARNING: THE USE OF AN OVERDRAW THAT ALLOWS A SHOOTER TO DRAW THE POINT OF THE ARROW PAST THE SHELF OF THE BOW SIGNIFICANTLY INCREASES THE RISK OF INJURY TO THE SHOOTER. When using a bow equipped with an overdraw the arrow should always be cut to a minimum of one inch in front of the arrow rest at full draw. Selecting the correct arrow length is the responsibility of the shooter and failure to do so could result in severe injury, and/or damage to shooting equipment. ARROW REST WARNING: Before shooting any Gold Tip arrows it is extremely important to inspect the arrow rest to ensure that it is properly adjusted to fit the diameter of the arrow shaft being used. FAILURE TO PROPERLY ADJUST THE ARROW REST SIGNIFICANTLY INCREASES THE RISK OF INJURY TO THE SHOOTER AND DAMAGE TO SHOOTING EQUIPMENT. Incorrect adjustment of the arrow rest may cause the arrow to fall from the arrow rest and/or get jammed in the bow which could result in injury to the shooter or bystanders, and damage to shooting equipment. ALWAYS MAKE CERTAIN THAT THE ARROW REST IS PROPERLY ADJUSTED BY A QUALIFIED INDIVIDUAL BEFORE SHOOTING. ARROW INSPECTION WARNING: INSPECT EACH ARROW FOR DAMAGE PRIOR TO EVERY SHOT. Proper care of carbon arrows can ensure years of quality performance. However, shafts can be damaged. To inspect an arrow, grasp it on both ends and flex it away from yourself and others while visibly and audibly checking for splinters, cracks or nicks. Rotate and repeat this inspection process four to five times around the entire circumference of the shaft. If you find an arrow to be damaged in any way discard it immediately. SHOOTING DAMAGED CARBON ARROWS CAN RESULT IN ARROW FAILURE AND POSSIBLE INJURY. CUTTING CARBON ARROWS: Cut carbon arrows using a high speed arrow cut off saw only. Use of any other type of saw may cause damage to the arrow.The Flex it First logo is our way of reminding you to flex each shaft to test it for safety periodically – especially after shooting groups or if you miss a target. Why? Every Gold Tip arrow leaves our factory as the toughest, safest arrow we can make. But like every product, there’s a chance that your arrows could sustain damage in shipping, stocking, and shooting that isn’t visible to the eye. Simply flex your arrows before shooting to be sure that your arrow is not damaged. If there is damage, you will see the carbon seperate or the shaft will break. That way, you’ll keep shooting safe and straight. Damn Straight.

Custom Made Arrows usually dispatched within 5-7 working days Mon-Fri - (Excluding Wednesdays & Bank Holidays)

• We do our best to keep items indicated 'stocked' available from our physical stocks, but please note stock levels are not live.

• Custom order items typically take 7-21 days to dispatch unless otherwise stated.

If urgent or travelling to our showroom, please always call or email so we can confirm availability.

Mainland UK Shipping Guide:

Small items from - £4Single Parcel (up to 20kg) from - £10

Click & Collect - FREE - Please do not to travel to our showroom until we notify you that your order is ready to be collected.